HKF 30/14-E

59801310 (05/24)

59801310 (05/24)

Read the original instructions before using the device for the first time and act in accordance with it. Keep this document for future reference or for future owners.

Read the original instructions before using the device for the first time and act in accordance with it. Keep this document for future reference or for future owners.

If the operating instructions and safety instructions are not observed, the device can be damaged and dangers could arise for users and other persons.

Notify the dealer immediately in the case of shipping damage.

Check the package contents when unpacking for missing accessories or for damage.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

The packing materials can be recycled. Please dispose of packaging in accordance with the environmental regulations.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Electrical and electronic devices contain valuable, recyclable materials and often components such as batteries, rechargeable batteries or oil, which - if handled or disposed of incorrectly - can pose a potential danger to human health and the environment. However, these components are required for the correct operation of the device. Devices marked by this symbol are not allowed to be disposed of together with the household rubbish.

Current information on content materials can be found at: www.kaercher.de/REACH

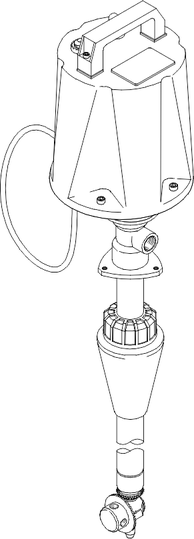

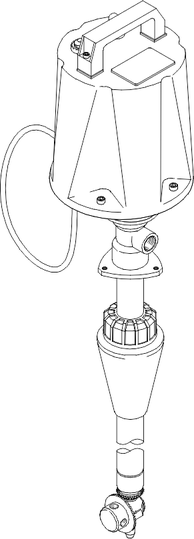

The HKF 30/14-E interior cleaner is a spray unit for cleaning bung containers according to DIN, as well as other containers and barrels.

The cleaning head is brought into the container through an opening with a minimum diameter of 65 mm.

A separate high-pressure pump is connected to the interior cleaner using a high-pressure hose.

Operation outside of closed containers, operation at higher pressures and higher temperatures than those specified in the technical data is regarded as improper use.

The device may only be operated with the following cleaning fluids:

Water

Fully desalted water

Water with alkaline detergent (max. 0-2%)

Water with acidic detergent (max. 0-1%)

Only KÄRCHER detergents may be used.

The device may not be operated in explosive environments.

The device must not be operated with explosive and flammable substances!

Do not allow waste water containing mineral oil to penetrate soil, waterways or the sewage system.

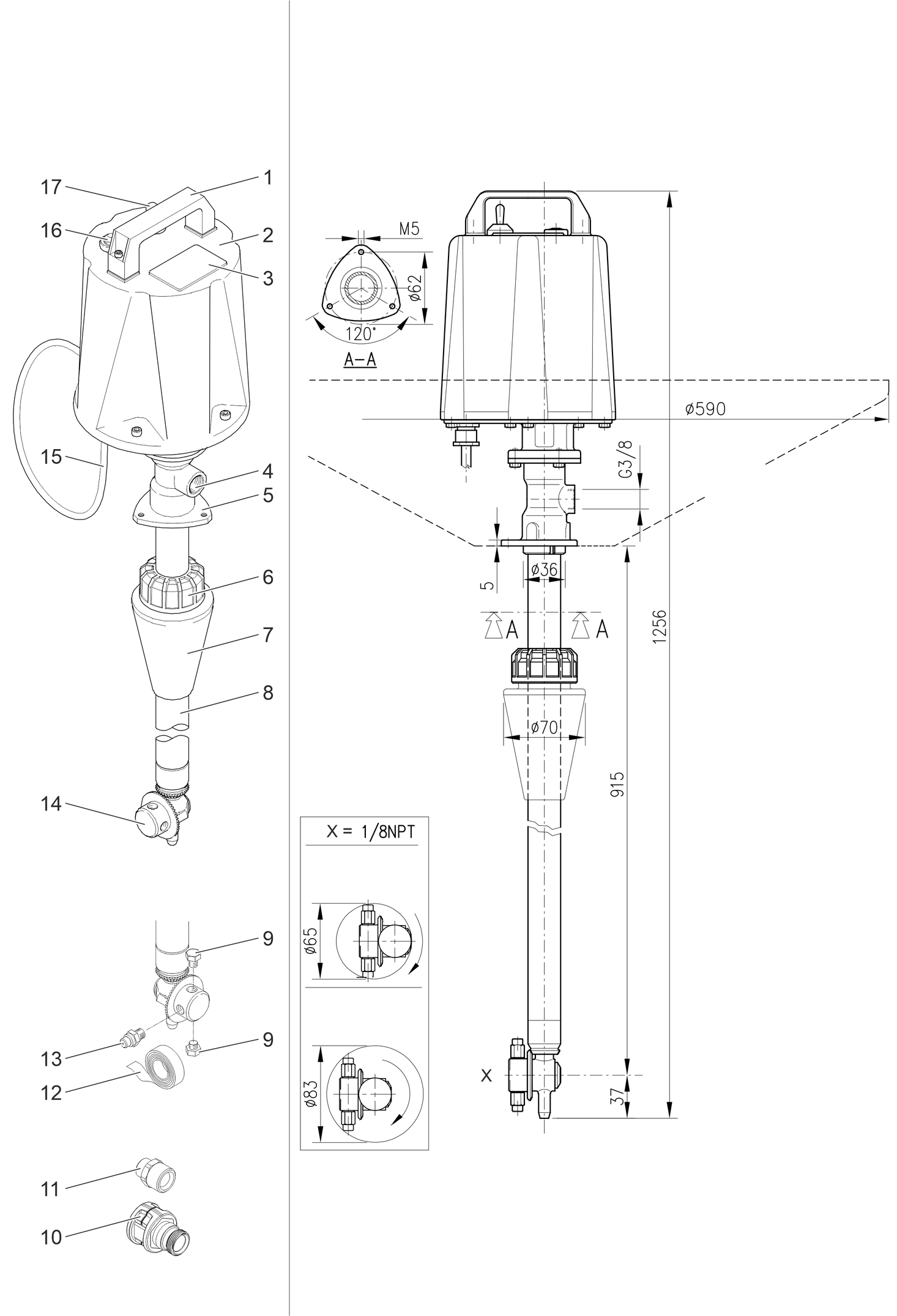

The interior cleaner consists of the drive part, the carrier tube and the cleaning head. The nozzles on the cleaning head rotate around two axles and thus cover every part of the container.

The cleaning head rotates by means of an electric motor. The rotary speed is therefore constant and not dependent on the pressure and volume of cleaning fluid.

There is an adjustable bunghole cone on the support tube which is placed on the opening of the container.

Observe the applicable national regulations.

Observe the safety instructions provided with the detergent used (usually on the packaging label).

To prevent dangers due to incorrect operation, the system may only be operated by persons who have been instructed in the handling of the system, who have verified their ability to operate the system and who have been authorised and commissioned to use the system.

The operating instructions must be accessible to all operators.

The high-pressure pump used must be equipped with all the safety devices specified by the corresponding CE marking.

Observe the operating instructions and the safety instructions for the high-pressure pump used.

Incorrect operation or misuse of the device can endanger the operator and other persons through:

high pressure

high electrical voltage

Detergent or cleaning fluid used

Danger of crushing due to the drive of the interior cleaner. Only operate the interior cleaner drive in closed containers.

There is risk of injury from the escaping high-pressure jet. Therefore, only operate interior cleaners in closed containers.

Health hazard from residues in the containers being cleaned or from the cleaning fluid used. Therefore, follow the prescribed protective measures.

Risk of injury from the interior cleaner falling over at low immersion depth. In this case, secure the interior cleaner additionally.

There is a danger of injury due to the container falling over. Therefore, additionally secure the container and interior cleaner.

To avoid damage to the cleaning head, ensure that it is positioned freely in the container. The cleaning head must not hit the container wall under any circumstances.

Authorised operators are persons who have reached the age of 18 and are qualified to operate this system (exceptions for trainees, see BGV D15 §6).

Switch off the separate high-pressure pump.

Pull out the mains plug.

Close the cleaning fluid supply.

The use of a dirt filter in the water line is recommended, but the filter should be cleaned regularly.

Danger from high electrical voltage

Lethal danger

Only have the required electrical installation carried out by a qualified electrician.

A power supply is not included in the scope of delivery.

The socket must be protected by a fault current protection switch with a trigger current of 30 mA.

The socket must be close to the workplace so that the mains plug can be pulled out quickly in an emergency.

Position the on-site power supply so that it is protected from spray water. If this is not possible, a waterproof power supply must be used.

The interior cleaner is equipped with 2 screw plugs as standard. The spray nozzles must be ordered separately.

Depending on the flow rate and the pressure of the high-pressure pump, different spray nozzles can be used (see tables).

Before switching on the high-pressure pump, the minimum pressure value of the control valve must be set. In this way, the interior cleaner is not subjected to pressure peaks during start-up.

Operation with 2 nozzles | ||||

Flow rate l/h (l/min) | 800 (13,3) | 1000 (16,7) | 1000 (16,7) | 1100 (18,3) |

Pressure MPa (bar) | 10 (100) | 9,5 (95) | 14 (140) | 8 (80) |

Nozzle size | 03 | 04 | 03 | 045 |

Part number | 6.415-444.0 | 6.101-060.0 | 6.415-444.0 | 6.415-446.0 |

Number of nozzles | 2 | 2 | 2 | 2 |

Number of screw plugs | 2 | 2 | 2 | 2 |

Operation with 2 nozzles | ||||

Flow rate l/h (l/min) | 1200 (20) | 1500 (25) | 1800 (30) | 2400 (40) |

Pressure MPa (bar) | 10 (100) | 10 (100) | 14 (140) | 10 (100) |

Nozzle size | 045 | 055 | 055 | 09 |

Part number | 6.415-446.0 | 6.415-445.0 | 6.415-445.0 | 6.415-447.0 |

Number of nozzles | 2 | 2 | 2 | 2 |

Number of screw plugs | 2 | 2 | 2 | 2 |

Operation with 4 nozzles | ||||

Flow rate l/h (l/min) | 2000 (33,3) | 2200 (36,7) | 2400 (40) | 3000 (50) |

Pressure MPa (bar) | 9,5 (95) | 8 (80) | 10 (100) | 10 (100) |

Nozzle size | 04 | 045 | 045 | 055 |

Part number | 6.101-060.0 | 6.415-446.0 | 6.415-446.0 | 6.415-445.0 |

Number of nozzles | 4 | 4 | 4 | 4 |

Number of screw plugs | - | - | - | - |

Operation with 1 nozzle | |||

Flow rate l/h (l/min) | 600 (13,3) | 750 (16,7) | 1200 (16,7) |

Pressure MPa (bar) | 6,5 (65) | 10 (100) | 10 (100) |

Nozzle size | 055 | 055 | 09 |

Part number | 6.415-445.0 | 6.415-445.0 | 6.415-447.0 |

Number of nozzles | 1 | 1 | 1 |

Number of screw plugs | 3 | 3 | 3 |

Part number for screw plug: 5.411-061.0

Mount the spray nozzles or screw plugs with Teflon tape.

Place the interior cleaner with the bunghole cone sitting on the carrier tube on the object to be cleaned.

Release the screw connection on the bunghole cone.

Set the immersion depth.

Tighten the screw connection on the bunghole cone.

Connect the separate high-pressure pump to the indoor cleaner using a high-pressure hose.

High-pressure jet

Risk of injury from escaping, possibly hot high-pressure jet

Only operate the interior cleaner in containers that are closed on all sides.

Switch off the separate high-pressure pump and the interior cleaner's own drive if you want to insert the interior cleaner into the container or transfer it to another container.

Try to arrange the interior cleaner centrally.

Recommendation: Carry out 1 cleaning cycle if the container is slightly to moderately soiled and 2 cleaning cycles if it is heavily soiled. The duration per cycle is 6 minutes.

Connect the interior cleaner to the on-site power supply.

Connect the mains plug.

Open the cleaning fluid supply.

Switch on the separate high-pressure pump.

Switch on the interior cleaner at the power switch. The indicator light lights up.

Perform cleaning.

Rinse the interior cleaner for 30 seconds without adding detergents before shutting down. This prevents encrustation and sticking and thus premature wear and tear of the seals.

Switch off the interior cleaner at the power switch. The indicator light goes out.

Pull out the mains plug.

Switch off the separate high-pressure pump.

Close the cleaning fluid supply.

Remove the interior cleaner from the container.

Failure to observe the weight

Risk of injury and damage

Be aware of the weight of the device during transportation.

When transporting the device in vehicles, secure it to prevent it from slipping or overturning in accordance with the respective valid guidelines.

Failure to observe the weight

Risk of injury and damage

Be aware of the weight of the device during storage.

Regular maintenance is essential for a safely operating system.

Inadvertently starting up device, touching live components

Risk of injury, electric shock

Switch off the device before performing any work on the device.

Remove the mains plug.

Disconnect the separate high-pressure pump from the main switch and secure it.

Close the cleaning fluid supply.

Unscrew the high-pressure hose from the interior cleaner.

Allow the interior cleaner to cool down.

We recommend that you close a service contract to ensure reliable operation of the system. Please contact your KÄRCHER customer service department responsible.

Remove any contamination in the area of the toothing on the cleaning head.

Check that all screws are tight.

Inadvertently starting up device, touching live components

Risk of injury, electric shock

Switch off the device before performing any work on the device.

Remove the mains plug.

The interior cleaner is designed for clockwise operation only (as seen from the gear motor). If the power supply unit is replaced or if the electrical connections are interfered with, it must be checked afterwards whether the interior cleaner still rotates in the right direction.

Disconnect the separate high-pressure pump from the main switch and secure it.

Close the cleaning fluid supply.

Unscrew the high-pressure hose from the interior cleaner.

Allow the interior cleaner to cool down.

Operator: Work labelled with "Operator" may only be performed by instructed persons capable of operating and maintaining high-pressure systems.

Qualified electrician: Work labelled with "Electrician" may only be performed by qualified electricians.

Customer Service: Work labelled with "Customer service" may only be performed by KÄRCHER customer service technicians or KÄRCHER-authorised technicians.

Motor does not rotate

Cause:

No voltage at the motor

Remedy:

Check the fuse, the power supply unit and the cables (qualified electrician).

Cause:

The fault current protection switch has triggered

Remedy:

Remedy the cause and reset the fault current protection switch (qualified electrician).

Cause:

Interior cleaner switched off

Remedy:

Switch on the interior cleaner at the power switch (operator).

Motor rotates, cleaning head does not rotate

Cause:

Drive parts in the carrier tube are broken

Remedy:

Check the parts, replace the defective parts (Customer Service).

The Cleaning head rotates only around one axis or jerkily

Cause:

The cleaning head bumps against the container wall

Remedy:

Change the arrangement of the cleaning head and thereby ensure free running (operator).

Cause:

The tooth clearance of the bevel gears is too large

Remedy:

Readjust the bevel gears, replace the worn parts (Customer Service).

Cause:

Destroyed teeth of the bevel gears

Remedy:

Replace the bevel gears (Customer Service).

Uneven cleaning jet

Cause:

Spray nozzles are clogged

Remedy:

Clean the spray nozzles (operator).

Cause:

Spray nozzles are damaged

Remedy:

Replace the spray nozzles (operator).

Spraying quantity is too low

Cause:

Leakage at the cleaning head or in the supply line

Remedy:

Check the high-pressure pump, check the pressure lines/hoses (operator).

Cause:

Dirt filter in the supply line is clogged

Remedy:

Clean the dirt filter (operator).

Cleaning fluid leaks to the drain holes of the carrier tube in considerable quantities.

Cause:

Mechanical seals in the carrier tube are worn out

Remedy:

Check the parts, replace the defective parts (Customer Service).

Significant pressure drop, but no leakage of cleaning liquid at the drain holes.

Cause:

Mechanical seals in the cleaning head are worn out

Remedy:

Check the parts, replace the defective parts (Customer Service).

If the malfunction cannot be corrected, the device must be checked by the Customer Service department.

Motor does not rotate

Cause:

No voltage at the motor

Remedy:

Check the fuse, the power supply unit and the cables (qualified electrician).

Cause:

The fault current protection switch has triggered

Remedy:

Remedy the cause and reset the fault current protection switch (qualified electrician).

Cause:

Interior cleaner switched off

Remedy:

Switch on the interior cleaner at the power switch (operator).

Motor rotates, cleaning head does not rotate

Cause:

Drive parts in the carrier tube are broken

Remedy:

Check the parts, replace the defective parts (Customer Service).

The Cleaning head rotates only around one axis or jerkily

Cause:

The cleaning head bumps against the container wall

Remedy:

Change the arrangement of the cleaning head and thereby ensure free running (operator).

Cause:

The tooth clearance of the bevel gears is too large

Remedy:

Readjust the bevel gears, replace the worn parts (Customer Service).

Cause:

Destroyed teeth of the bevel gears

Remedy:

Replace the bevel gears (Customer Service).

Uneven cleaning jet

Cause:

Spray nozzles are clogged

Remedy:

Clean the spray nozzles (operator).

Cause:

Spray nozzles are damaged

Remedy:

Replace the spray nozzles (operator).

Spraying quantity is too low

Cause:

Leakage at the cleaning head or in the supply line

Remedy:

Check the high-pressure pump, check the pressure lines/hoses (operator).

Cause:

Dirt filter in the supply line is clogged

Remedy:

Clean the dirt filter (operator).

Cleaning fluid leaks to the drain holes of the carrier tube in considerable quantities.

Cause:

Mechanical seals in the carrier tube are worn out

Remedy:

Check the parts, replace the defective parts (Customer Service).

Significant pressure drop, but no leakage of cleaning liquid at the drain holes.

Cause:

Mechanical seals in the cleaning head are worn out

Remedy:

Check the parts, replace the defective parts (Customer Service).

The warranty conditions issued by our sales company responsible apply in all countries. We shall remedy possible malfunctions on your device within the warranty period free of cost, provided that a material or manufacturing defect is the cause. In a warranty case, please contact your dealer (with the purchase receipt) or the next authorised customer service site.

You can find more detailed information at: www.kaercher.com/dealersearch

Only use original accessories and original spare parts. They ensure that the appliance will run fault-free and safely.

Information on accessories and spare parts can be found at www.kaercher.com.

We hereby declare that the machine described below complies with the relevant basic safety and health requirements in the EU Directives, both in its basic design and construction as well as in the version placed in circulation by us. This declaration is invalidated by any changes made to the machine that are not approved by us.

Product: Interior cleaner

Type: HKF 30/14-E

Currently applicable EU Directives2006/42/EC

2014/30/EU

Harmonised standards usedUNI EN ISO 12100: 2010

CEI EN 60335-1: 2013 + EC: 2014 + A11: 2015 + A13: 2018 + A13: 2019 + A1 A2 A14: 2019 + A1 A2 A14: 2021 + A15: 2022 + A15: 2013

CEI EN 55014-1: 2021

CEI EN 55014-2: 2021

The signatory acts on behalf of and with the authority of the company management.

President Arnaldo Benetti |

P.A. S.p.A.

Via Milano, 13

42048 Rubiera (RE) - ITALY

Rubiera, 21/11/2023

Electrical connection | |

Mains voltage | 24 AC V |

Phase | 1 ~ |

Power frequency | 50-60 Hz |

Degree of protection | IP40 |

Nominal power | 50 W |

Water connection | |

High-pressure connection | G 3/8 Inches |

Device performance data | |

Flow volume (max.) | 3000 (50) l/h (l/min) |

Cleaning fluid temperature (max.) | 90 °C |

Maximum operating pressure | 14 (140) MPa (bar) |

Functional speed of drive | 10 1/min |

Dimensions and weights | |

Typical operating weight | 4,95 kg |

Total length | 1256 mm |

Immersion depth (max.) | 915 mm |

Minimum container opening | 65 mm |

Ambient conditions | |

Ambient temperature | +2...+40 °C |